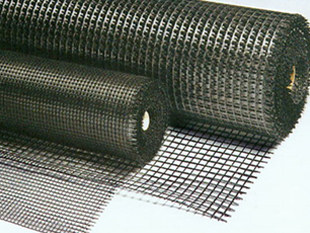

Discripition :

Geogrids are high strength oriented polymer grid structures used to reinforce soils & are made from high Tenacity polyester yarns, when coated with Poly Vinyl Chloride they make a strong, durable & dimensionally stable geogrid. Our product is highly recommended for reinforcement of soils & other granular materials for a wide variety of applications including soil retaining walls. Maruti Geogrid™ has good tensile strength, low elongational ratio & high occlusive force with soil or gravel which is ideal for soil reinforcement purposes. Maruti Geogrid™ is resistant to UV rays, bacteria attacks and aging resistant &has a product life of about 75 to 120 years.

TYPICAL APPLICATION:

GEOGRID REINFORCED EARTH (RE) WALL REINFORCED EARTH WALL HAVE EMERGED AS A TECHINCALLY TO CONVENTIONNAL RIGID CONCRETE RETAINING STRUCTURE.

DETERIORATION

- EASE AND SPEED OF INSTALLATION-PREFABRICATED MATERIALS ANND GRANULAR SOIL SIMPLIFY CONSTRUCTION.

- HIGH SATIC AND DYNAMIC LOAD CARRYING CAPABILITY.

- LOW MATERIAL AND INSRALLATION COSTS.

- EFFECTIVE UTILLZATION OF LAND.

- PLEASING APPEARACE-PANELS MAYBE GIVEN A VARIETY OF ARCHITECTURAL TREATMENNTS.

- RE WALL DISTRIBUTE LOADS OVER COMPRESSED SOILS, REDUCING THE NEED FOR DEEP FOUNDATIONS.

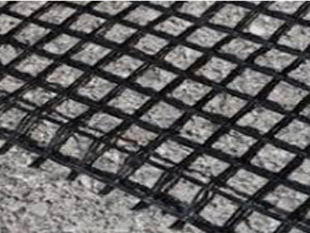

PAVEMENTS:

GEOGRIDS IN AGGEREGATE-SURFACED ROADS ARE USED TO SUPPORT MECHANICAL SUBGRADE STABILIZATION AND AGGREGATE BASE REINFORCEMENT.

ADVANTAGES:

- INCREASE THE PASSIVE BEARING CAPACITY OF GRANULAR BASE COURSE MATERIAL.

- PREVENT LOCALIZED OVERSTRESSING OF THE SUBGRADE THUS REDUCING PAVEMENT DETROIRATION.

- MINIMIZED BASE COURSE THICKNESS REQUIREMENT

- THE GRID STRUCTURE PROVIDES OPTIMUM INTERACTION IN ALL TYPE OF SOIL.

RAIL TRACK SUPPORT:

GEOGRID CAN BE USED FOR REINFORCEMENT OF A GRANULAR SUB-BASE LAYER BENEATH THE RAILWAY BALLAST TO INCREASE THE BEARING CAPACITY OF THE TRACK FOUNDATION.

ADVANTAGES:

MAINTAIN TRACK GEOMETRY FOR LONGER. REDUCE THE RATE OF BALLAST SETTLEMENT. REDUCE MAINTENACE INDUCED BALLAST DETERIORATION. EXTEND THE MAINTENANCE CYCLE BY A FACTOR OF AROUND THREE. STABILIZE BALLAST FOR OVER 25 YEARS.

WHY SIDDHI GEOGRIDE

WE HAVE INCORPORATED ADVANCED MULTISPEED MACHINE FOR HIGH QUALITY GEOGRID PRODUCTION, WHICH ENABLE US GEOGRIDS WITH VERY HIGH JUNCTION STRENGTH

MARUTI GEOGRIDS ARE PRODUCED FROM HIGH MOLECULAR WEIGHT,LOW CEG HIGH TENACITY POLYESTER (PET) YARNS WITH:

AVERAGE MOLECULAR WEIGHT >25000

CARBOXYL END GROUPS >30.

OUR GEOGRIDS ARE INERT TO ENVIROMENTAL EFFECTS, AND RETAINS HIGH STRENGTH FOR ABOUT 75-120 years, depending upon project design and requirements.