Advantage Of Neoprene Elastomeric Brearing Pad

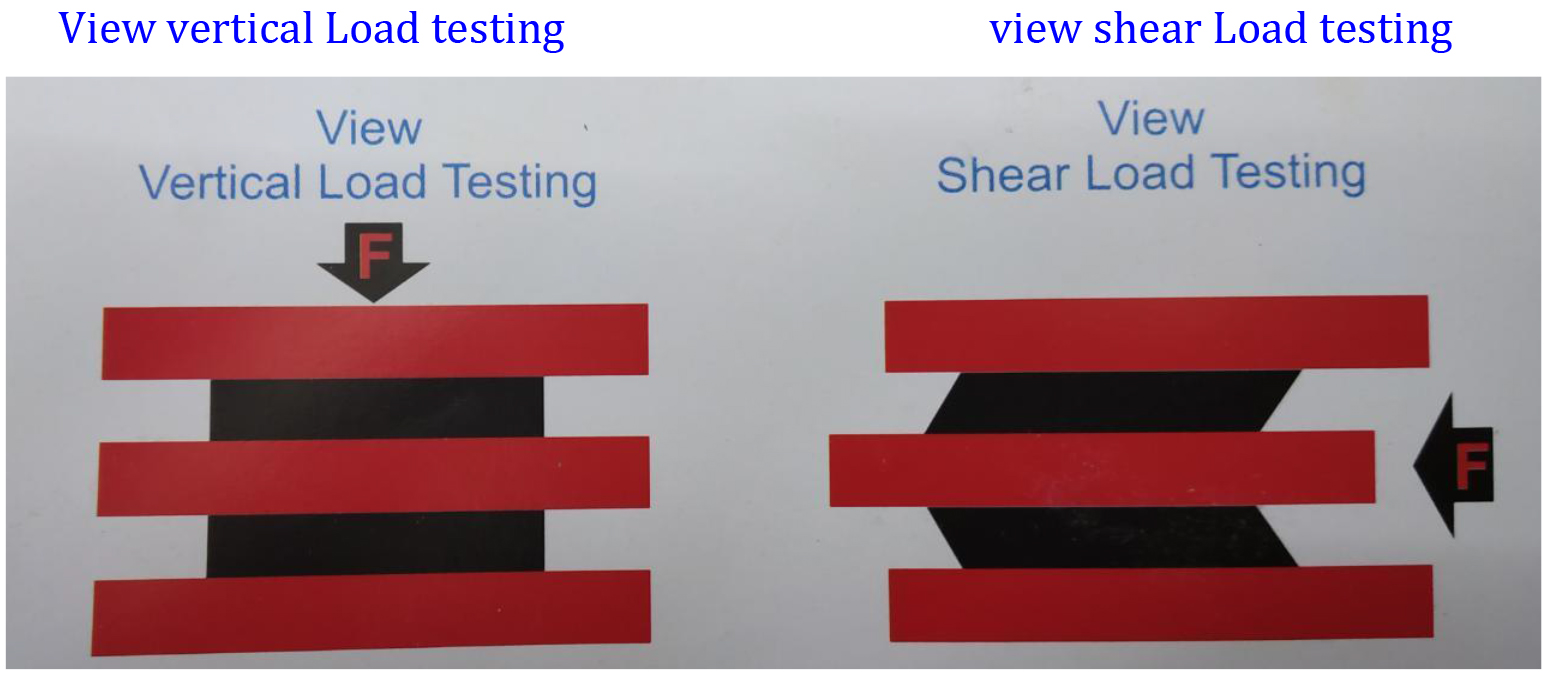

AS efficient bearing plates for pre- cast, pre-stressed concrete or steel beams In Bridges and building, neoprene pad- plane and laminated –Manufactured By Siddhi permits a smooth and uniform transfer of load from the beam to the Substructure and allow beam rotation at the bearing. Due to deflection of the Beam under load. They further allow lateral and longitudinal movement of the Beam Caused by thermal forces. Neoprene pads have no moveable parts and Thermal Expansion and contraction are absorbed by the pads enable to give And take in Shear .There is no sliding motion Between Pad and beam or between Pad and Abutment.

Quality Control

Lab is equipped with latest instruments like Tensile, IRHD hardness Tester, tension set Apparatus, Air oven, Muffle furnace humidity Chamber, high voltage tester, Bi-Axial testing Machine, all instruments are calibrated from. NABL certified lab

Neoprenebear

Physical Properties as per standard

IRC-83(part- II)

With Steel Lamination

Physical Properties as per standard

IASTMD-15(Part B)

without Lamination

| SL. NO. | TYPE OF TEST | UNIT | SPECIFIED | UNIT | SPECIFIED DURO 50 | SPECIFIED DURO 60 | SPECIFIED DURO 70 |

|---|---|---|---|---|---|---|---|

| 1. | Tensile Strength (ASTMD-412) | Kgf/cm2 MPA | 175 Min | Kgf/cm2 Psi | 175 2500(17 Mpa) | 175 2500(17 Mpa) | 175 2500(17MPA) |

| 2. | Elongation at break (ASTMD-412) | % | 400 min | % | 450 | 400 | 300 |

| 3. | Hardness (ASTDM-2240) | Shore –A | 60±5 | Duro Meter | 50±5 | 60±5 | 70±5 |

| 4. | Compression Set (ASTDM-395) | % | 35 max 1000 Cx22HRS | % 700 Cx22HRS | 25 Max | 25 Max | 25 Max |

| 5. | Aging test (ASTDM-573) at 1000 For Hour a. change in tensile strength b. change in elongation c. change in hardness |

% % Shore-A |

-15 Max -40 Max +15 |

% % Duro Meter |

±15 Max ±40 Max ±15 Max |

±15 Max ±14 Max ±15 Max |

±15 Max ±14 Max ±15 Max |

| 6. | Adhesion Test | KN/mtr | 7 min | - | - | - | - |

| 7. | Shape Factor | - | - | 6-12 | - | - | - |

| 8. | Tear Resistance (ASTDM 624) | - | - | Kgf/cm2 | 45 min | 45 min | 45 min |

| 9. | Ozone resistance (ASTDM1149) At (1ppm in air by volume/20%) Strain/38+1 0 c)100 hours |

- | No crack | - | No Crack | No Crack | No Crack |

| 10. | Low temperature stiffness at (-4.40 C young’s modulus (ASTDM-797) | - | - | Kgf/cm2 | 700 10,000 |

700 10,000 |

700 10,000 |

Bi-Axial Testing Machine

Calendaring Machine

Neoprene Bearing Pad

Technical Data Sheet:

PLAN DIMENSION SHOULD BE AS PER SERIES

| lo | overall length |

| bo | over all width |

| l | Effective length (excluded side cover) |

| b | Effective width (excluded side cover) |

| c | Thickness of side cover |

| h | Total height of elastomer |

| hs | Thickness of steel plate |

| hi | Thickness of elastomer |

| he | Thickness of top/bottom elastomer |

| n | .No of layers of elasstomer |

Total thickness of Bearing pad

H=n. Hi+2. He+(n+1).Hs

| 1. | lo/bo<2 | |

| 2. | hi(mm) (Thickness of polymer) |

8 10 12 16 |

| 3. | hs(mm) (Thickness of steel plate) |

3 3 4 6 |

| 4. | C(thickness of side cover) | 6 |

| 5. | S(shape factor) | 6 to 12 |

| Size | Effective Area Ax10-4mm | Max. Loan Nmax KN | Min. Loan At20 MpaKN | Polymer Thickness hi(mm) | No. of Layers | Total Height h(mm) | Shape Factor S | Elastic Modulus Mpa | Shear Modulus kgf/cm 2 | Hardnew Store-A |

|---|---|---|---|---|---|---|---|---|---|---|

| 200x350 | 6.35 | 635 | 127 | 8 | 4 | 40 | 7.91 | 325 217 | 9.22 | 57 |

| 250x300 | 6.85 | 685 | 137 | 8 | 5 | 48 | 8.14 | 342 228 | 342 228 | 56 |

| 250x400 | 9.23 | 923 | 185 | 10 | 4 | 50 | 7.37 | 286 190 | 9.25 | 57 |

| 250x500 | 11.16 | 1161 | 232 | 10 | 4 | 50 | 8.00 | 334 222 | 9.15 | 56 |

| 300x400 | 15.00 | 117 | 223 | 10 | 4 | 60 | 8.26 | 353 235 | 9.30 | 57 |

| 320x500 | 15.00 | 1500 | 300 | 10 | 5 | 60 | 9.44 | 444 293 | 9.65 | 60 |

| 350x450 | 14.80 | 1480 | 296 | 12 | 5 | 72 | 7.95 | 328 218 | 9.4 | 59 |

| 300x600 | 16.93 | 1693 | 339 | 10 | 5 | 60 | 9.66 | 461 308 | 9.22 | 57 |

| 400x400 | 15.05 | 1505 | 301 | 12 | 5 | 72 | 8.08 | 342 228 | 9.65 | 60 |

| 450x500 | 18.93 | 1893 | 379 | 12 | 5 | 72 | 9.00 | 406 270 | 9.42 | 59 |

| 400x800 | 30.60 | 3100 | 600 | 12 | 5 | 72 | 10.83 | 534 356 | 9.35 | 58 |

| 550x550 | 28.94 | 2900 | 579 | 12 | 5 | 72 | 11.20 | 574 382 | 10.55 | 62 |