Retaining Earth (RE) walls are used in bridges, highways and large infrastructure projects to support soil and prevent erosion. One of the most important parts of an RE wall system is the RE Wall Panel Rubber Pad a small component that plays a big role in safety, durability and performance.

In this blog, we’ll explain what these rubber pads are, how they work, why EPDM rubber is used, and why industries trust Siddhi Rubber Udyog for high-quality RE Wall Rubber Pads.

What Are RE Wall Panel Rubber Pads?

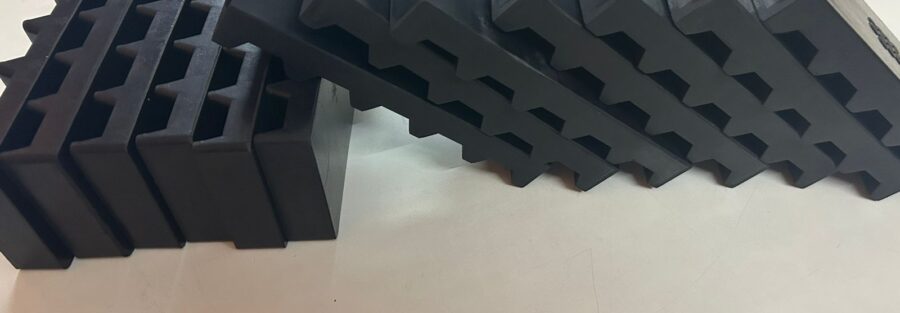

RE Wall Rubber Pads are specially designed EPDM rubber sheets placed between concrete panels of retaining walls.

Their main job is to:

✔ Maintain proper spacing between panels

✔ Absorb vibration caused by heavy loads

✔ Reduce stress on the structure

✔ Prevent cracks and panel damage

These pads act like a cushion, improving the flexibility and life of the wall system.

Read More: Garden Drain Cell

Why EPDM Rubber Is Used for RE Wall Pads?

EPDM (Ethylene Propylene Diene Monomer) is one of the most widely used rubber materials in construction. It is known for:

- Excellent weather resistance

- UV, ozone and heat stability

- Good flexibility in hot and cold climates

- Long life and low maintenance

- Cost-effectiveness compared to silicone

Because highways and bridges face extreme outdoor conditions, EPDM is the perfect material for RE wall applications.

However, EPDM is not suitable for use with petroleum-based oils and solvents. For such applications, alternative materials are recommended.

How RE Wall Rubber Pads Are Manufactured?

At Siddhi Rubber Udyog, the pads are made using a compression moulding process, known for delivering strong and consistent rubber components.

Step-by-Step Manufacturing Process

- Raw Material Selection: High-quality EPDM rubber is chosen based on project specifications.

- Weighing & Pre-forming: The uncured rubber is measured to control thickness and shape.

- Moulding: The rubber is placed inside a mould cavity and pressed under heat and pressure.

- Curing: Heat activates the curing chemicals, giving the pad its final strength and properties.

- Finishing: The cured pads are removed, trimmed and checked for quality.

Read More: Non Woven Geotextiles

Key Features of Siddhi Rubber Udyog’s RE Wall Rubber Pads

We provide the best Architect & Interior Design Services

Our rubber pads are designed to perform under tough real-world conditions. Key features include:

- High Tensile Strength: Ensures the pad can withstand heavy load and compression.

- Superior Weather Resistance: Withstands extreme heat, cold and moisture without cracking.

- Excellent Vibration Absorption: Protects structure from shock and movement.

- Long Service Life: Less maintenance required over the years.

- Chemical Stability: Resistant to ozone and aging, ensuring long-term reliability.

Technical Specifications (Simplified)

Here’s an easy-to-understand view of the main technical properties of our EPDM RE Wall Pads:

Hardness: 85 ± 5

Tensile Strength: 11 MPa minimum

Elongation at Break: 400%

Compression Set: Max 25%

Ozone Resistance: Retention min 85%

Density: 1.3 ± .03

Color: Black

These properties make EPDM pads suitable for heavy-duty infrastructure work.

Why Choose Siddhi Rubber Udyog?

Siddhi Rubber Udyog is known for manufacturing high-performance rubber products for the construction industry. Our RE Wall Panel Rubber Pads are trusted for use in bridges, retaining walls, road projects and various civil engineering applications. We continues to deliver top-quality RE Wall Rubber Pads that meet international standards and ensure long-lasting structural integrity.